Home appliances | Lighting | Electrical Accessories | Computer Device | Power tools | Electronic equipment

Each year, individuals are seriously injured or killed by seasonal lighting, including holiday lights and decorative outfits, that use undersized wiring, use insufficient strain relief, or omit fuses.

GIS Inspection(General Inspection Service) is a global provider in lighting quality control inspection services. For total quality assurance across safety, performance, and quality, GIS has the expertise to quickly bring lighting products to global markets.

Our highly experienced team of inspectors is well-versed with the lighting quality control standards. It can help you ensure that your lighting products meet the highest standards of safety, efficiency, and visual comfort.

Content

Lighting Quality Control Inspection and Quality Assurance

Lighting quality control inspection and quality assurance refer to the process of evaluating and verifying the quality, performance, safety, and labeling of lighting products, including ceiling lights, wall lights, table and desk lamps, floor lamps, night lights, decorative lights, and bulbs to ensure they meet specific standards, regulations, and customer requirements.

GIS Inspection provides assurance to consumers, retailers, and regulatory authorities that lighting products are safe, reliable, and perform as advertised. It also helps manufacturers to differentiate their products in the market and comply with legal and market access requirements.

Check: Lighting quaity control inspection and quality assurance.pdf

The Importance of Lighting Inspection

Lighting inspection is a crucial process in ensuring that lighting products meet safety, performance, energy efficiency, and regulatory compliance requirements before they reach the market. Proper inspection minimizes risks, enhances product quality, and ensures customer satisfaction. Below are the key reasons why lighting inspection is essential:

1. Ensuring Safety Compliance

Lighting products must comply with international and regional safety standards to prevent electrical hazards, overheating, and fire risks.

2. Verifying Product Performance and Quality

A lighting inspection ensures that products meet their intended brightness, color temperature, lifespan, and durability requirements.

3. Ensuring Energy Efficiency Compliance

Energy efficiency regulations require lighting products to meet strict efficiency levels.

4. Detecting Manufacturing Defects

Quality control inspections help identify critical, major, and minor defects in lighting products, such as wiring issues, loose connections, or defective components. Identifying defects early in production reduces waste, rework costs, and customer dissatisfaction.

5. Environmental and Sustainability Compliance

Inspections ensure compliance with environmental regulations, such as RoHS. Failure to meet environmental standards can lead to heavy fines and import restrictions.

Regulations and Standards for Lighting Quality Control

Lighting quality control is governed by various regulations and standards to ensure safety, performance, and energy efficiency. These standards are established by international, regional, and national organizations. Below is a comprehensive overview of the key regulations and standards for lighting quality control:

IEC/EN luminaires standards

The IEC develops global standards for electrical, electronic, and related technologies. Key lighting standards include:

- IEC 60598 Luminaires - Part 1: General requirements and tests: Safety of luminaires, covering general requirements and tests for all types of lighting fixtures.

- IEC 61347 Controlgear for electric light sources - Safety - Part 1: General requirements: Safety of control gear (e.g., ballasts, drivers) used in lighting systems.

- IEC 62471 Photobiological safety of lamps and lamp systems: Photobiological safety of lamps and lamp systems to evaluate risks such as UV or blue light hazards.

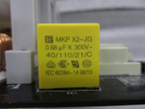

- IEC 60384-14: Fixed capacitors for use in electronic equipment - Part 14: Sectional specification - Fixed capacitors for electromagnetic interference suppression and connection to the supply mains.

Lighting Compliance Requirements in the US

To sell lighting products in the United States, manufacturers must comply with various safety, performance, energy efficiency, and environmental regulations.

- UL 1598 Luminaires: Safety standards for luminaires.

- UL 8750 Light Emitting Diode (LED) Equipment for Use in Lighting Products: Covers safety requirements for LED lighting components.

- UL 2108 Low Voltage Lighting Systems

- UL 1993 Self-ballasted lamps and adapters.

- FCC Part 15 – Electromagnetic Interference (EMI) Regulations: Lighting products with electronic components, such as LEDs, must meet FCC Part 15 (Subpart B) to ensure they do not cause harmful radio frequency interference.

- RoHS (Restriction of Hazardous Substances): Limits substances like lead, mercury, cadmium, and other toxic materials in electrical components.

Lighting Regulations and Standards in the EU

Companies importing and manufacturing lighting products for the EU market must ensure compliance with various regulations and directives.

CE marking

CE marking is a mandatory conformity certification for lighting products sold in the European Economic Area (EEA). It indicates that a product complies with the essential health, safety, and environmental protection requirements of the European Union (EU).

For lighting products, CE marking covers multiple EU directives and regulations related to electrical safety, electromagnetic compatibility, energy efficiency, and hazardous substances.

Regulation (EU) 2019/2020 laying down ecodesign requirements for light sources

Regulation (EU) 2019/2020 is an implementing measure under the Ecodesign Directive and establishes ecodesign requirements for light sources, including LED and OLED light sources, and separate control gear.

Ecodesign requirements

The regulation’s ecodesign requirements pertain to:

- Energy efficiency requirements

- Functional requirements

- Information requirements

Commission Delegated Regulation (EU) 2019/2015 on Energy labelling for light sources

Commission Delegated Regulation (EU) 2019/2015 supplements the Energy Labelling Framework Regulation and establishes requirements for the following:

- Light sources with an integrated control gear

- Light sources without an integrated control gear

- Light sources that are contained in another product

RoHS Directive

The RoHS Directive establishes restrictions regarding hazardous substances in electrical and electronic equipment (EEE), such as lighting equipment.

Types of Third-party Lighting Quality Control Inspection Service

Different types of inspections are performed at various stages of the lighting products manufacturing process. These include:

Pre-Production Inspection(PPI)

Before the actual production commences, the pre-production assessment takes place. During this phase, inspectors examine and verify the quality of individual components that will be used in the lighting fixtures, such as bulbs, LEDs, wiring, housing materials, and electrical components.

During Production Inspection (DUPRO)

The LED or other lighting parts will be examined for their appearance, construction, and function to ensure that quality requirements and specifications are met. Inspectors identify and rectify any defects, irregularities, or deviations from quality standards that may arise during production.

If issues are identified, inspectors collaborate with manufacturers to promptly implement corrective actions, preventing the production of substandard lighting products.

Pre-Shipment Inspection(PSI)

We will select a random sample of finished LED or other lighting products before shipment to ensure they meet the specified quality benchmarks and comply with safety regulations. The functionality of lighting features, such as switches, dimmers, and adjustable components, is tested to ensure optimal performance.

Inspectors supervise the packaging process to verify that the lighting products are adequately protected for transportation. They also ensure proper loading onto shipping containers to prevent damage during transit.

Loading Supervision (LS)

Generally conducted at the factory or port to verify count, confirm load and seal container prior to the container being sealed for export.

Audits for the Lighting Industry

Factory Audit: An independent assessment of the manufacturing facility’s capacity, machinery, and workforce to determine if they can meet production demands while maintaining product quality.

Supplier Audit: Checking the company’s legal information, bank information, human resources, export capabilities, and more. The inspectors perform supplier verification audit, evaluating

Essential Lighting Inspection Checklist during an onsite Inspection

Inspectors of GIS Inspection are conducting pre-shipment inspection for LED lighting in China

A comprehensive lighting PSI checklist is essential to ensure that all aspects of the product are inspected thoroughly. Here are some key areas to include in GIS quality assurance PSI checklist:

1. Quantity check

GIS inspectors count products and shipping cartons to verify that the correct quantity of an order has been finished which including PO quantity, shipment quantity, packed quantity, unpacked quantity, and unfinished quantity.

2. Workmanship Inspection

The inspector will select a sample size according to the statistical sampling procedure ISO 2859-1, and conduct a visual check for any damages and flaws in material and appearance and classify them as major, minor, or critical defects.

For the lighting products, third-party quality inspection agencies like GIS Inspection typically adopt AQL 1.5, 4.0.

Read more: How to Use AQL for Quality Control Inspection?

3. Product Description

GIS Inspection will verify that the products conform to the specifications against PO, photos, and sample.

4. On-site Safety Inspection

The selected sample will undergo rigorous testing to ensure that it functions properly and meets safety standards. The essential tests performed by our inspectors during an onsite inspection of garments and apparel:

- Hi-pot check

- Earth continuity check

- Polarity check

- Stain Relief test

- Internal Check

- Stability test

- Integrating sphere test

- Water Resistance test

- Transportation Drop test

- Product Size/ Power Cord Length/ Weight Measurement

- Barcode Scan Check

- Assembly/ Installation Check

- Full Function Check

- Coating Adhesive Tape Test

- Power on Check

- Power Consumption Check

- Rub and tape check

5. Packaging and labeling

GIS Inspectors verify that lighting products are properly labeled with relevant information such as wattage, voltage, safety instructions, and energy labels. The packaging should also provide adequate protection during transportation.

GIS inspectors will check the packing method and packing information to ensure that everything is accurate and safe for transportation. Inner and outer packaging are inspected to ensure that they meet client specifications, with results provided in the report.

Check a Free Sample Report for Lighting Inspection

GIS Inspection for you Lighting Quality Control

Established in China in 2005, GIS Inspection has developed a global business model focused on bringing your high-quality products to market faster than the competition. GIS Inspection specializes in conducting meticulous pre-production, during production, and pre-shipment inspections for lighting products.

What’s more, we not only inspection and test your products for both domestic and international markets, but we also provide the industry’s most comprehensive quality management solution. Our services encompass assurance, testing, inspection, and certification, helping you reduce risk and gain a competitive edge!

The team of inspectors at GIS Inspection possesses in-depth expertise and experience in lighting quality control. Their acute attention to detail guarantees a thorough evaluation of every facet of your lighting products, from functionality to aesthetics.

Book Your Lighting Inspection Today!